Delays with your suppliers create headaches with your inventory management, resulting in a scarcity of your product. If it’s a sought-after item, these delays can often come at the worst possible time. Knowing which products are hot items and those that are cooling off allows you to jump on new opportunities and adjust your stock to meet increased demand. The reorder point is key for business owners to determine how much safety stock a business should keep on hand as a buffer for excess demand. See first-hand how Extensiv can help you optimize stock levels to meet consumer demand and drive profitable growth, request a demo. However, factoring reorder points and safety stock into your replenishment calculations will help you better manage your current inventory and future order quantity.

Pay Attention to More than Your Reorder Point

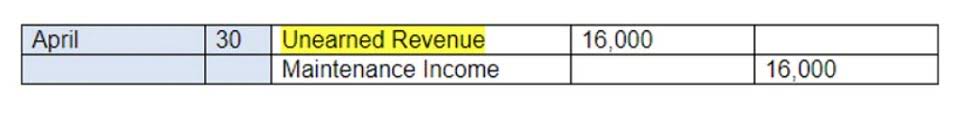

An ROP definition would explain that the reorder point is the trigger when a new order is generated. A level forecast pushed into the supply plan differs from reordering points regarding ordering quantities and order frequencies. Reorder points are a non-forecast or consumption-based planning method. That is, they are triggered by stock dropping below the reorder point.

How 3PLs Support Multi-Channel Fulfillment During Holiday Peaks

Whether using a spreadsheet or a system like Extensiv’s inventory and order management solution, the more efficiently you manage your reorder point (and your safety stock), the better you’ll meet demand. Neglected inventory management leads to a https://www.bookstime.com/ decrease in customer loyalty, in addition to lost sales. Negative reviews can quickly erode any positive online presence you’ve built. Next, a reorder point must consider a supplier’s lead time or the amount of time it takes for an ordered shipment to arrive. The daily sales velocity, or the average number of units you sell per day, differs for everything you sell. You also have enough safety stock units – to cover problems with Supplier B (or any point along the supply chain) or a sudden increase in demand.

Standard Deviation of Lead Time

Your lead time is the amount of time it takes a supplier to send the keyboards from the moment they receive a purchase order. Let’s assume for the purpose of this example that it takes your supplier 5 days, at the most, to deliver new keyboards. Your average daily usage is the average amount of keyboards you sell every day. You can find this number by adding up your daily orders and dividing it by the number of days in the period. For payroll instance, if you add up thirty days of orders and get 300, you would divide it by 30.

- The calculation for safety stock can range from a simple, fixed number to more complex statistical formulas based on historical demand and lead time variations.

- Failure to adjust those key variables won’t give you an accurate ROP when demand increases.

- When it comes to practical application, implementing the ROP in your business is a strategic move that can significantly enhance your inventory management.

- Many aspects of your business rely on third parties to keep operations running smoothly.

- By measuring the return on promotion, businesses can make data-driven decisions and optimize their marketing strategies to achieve the best possible results.

The sales or manufacturing rate, or demand rate, also differs per item and is a function of consumption over time. It is usually the average daily usage or average sales per day of an item. In the above graph, the demand rop meaning business rate of an item is represented by the stock level’s (green line) angle. ○ Express lead time in days for consistency with average daily demand.

How to calculate ROP with different vendors

- You omnichannel fulfillment partner that’s an extension of your brand, from unboxings to 2-day shipping.

- Some companies also include safety stock in their calculations to ensure they never run out of product.

- Explore AI tools and inventory management solutions designed to optimize your business operations and boost efficiency.

- At its core, the ROP formula is a blend of careful calculation and strategic foresight.

- It is thus an instrumental part of the ROP calculation and helps to avoid inventory levels falling below the safety stock line.

Whatever the case, review your reorder point policies regularly, depending on the requirements of your business. Your suppliers might also carry pressure points that can change at any moment. Market conditions might gradually or suddenly move in unexpected directions.

Reorder point formula FAQs

Observe that the forecast for the future (shown by the green line) is a level forecast. Before MRP software existed, some people in companies calculated requirements this way. They did this primarily by doing the math with calculators and using a table. This logic of requirements planning was then migrated to the software. Different reorder points can be set for different sales channels, locations, or based on seasonality.

Recent Comments